[ad_1]

Thermal administration is a crucial requirement for the protection and efficiency of EVs. Poor thermal administration might lead to thermal runaway occasions, making a hazardous fireplace situation. Additionally, poor thermal administration reduces the digital elements’ effectivity as a result of extreme warmth will increase electrical resistance and lowers the ability and power of the EV. It’s, subsequently, necessary to take away warmth from battery and powertrain elements effectively.

What’s Battery Security?

Typically, battery security encompasses defending the battery system from a number of opposed circumstances – electrical, thermal and environmental circumstances. The aim behind battery security is to offer a secure and dependable battery pack operation in all conditions, in addition to reduce the losses in case of hazardous occasions equivalent to battery thermal runaway.

Security Hazards

Electrical security: With excessive voltage elements in an assembled battery pack, it turns into extremely necessary to maintain these excessive voltage elements remoted. In any other case, an arcing occasion or electrical brief can compromise battery life and even worse can result in thermal runaway and eventual battery fireplace. Such electrical isolation may be included in a battery pack with use of dielectric coatings, hole fillers and seals.

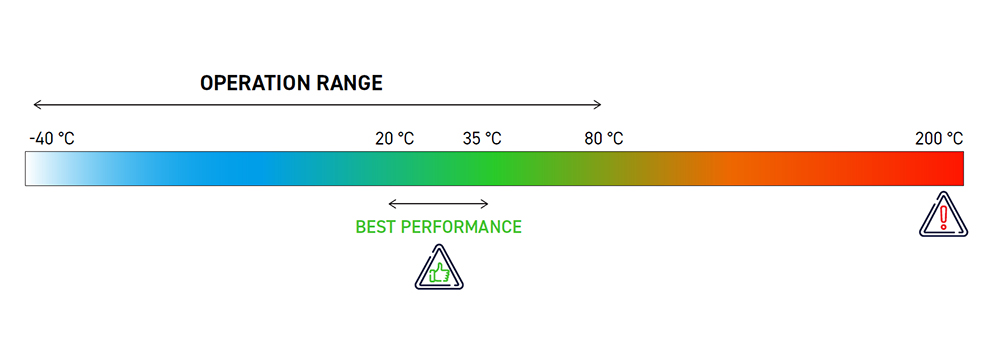

Thermal hazards: The Li-ion batteries function most effectively inside a good temperature vary of 20 to 35 °C. As a consequence of electrochemical reactions inside a battery whereas it’s charging or discharging, lots of warmth is generated. If the warmth dissipation shouldn’t be managed property, that may compromise battery efficiency and in worst case, result in thermal runaway. A well-engineered energetic temperature management system permits for battery pack to function in optimum temperature vary. The environment friendly temperature management is supplied by thermally conductive and electrically isolating interface supplies. These are utilized in between warmth supply (battery) and warmth sink (cooling plate/ribbon).

Environmental isolation: The high-voltage batteries may be delicate to moisture. The person battery packaging permits for moisture isolation. Nevertheless, redundant options should be included in battery pack design for added security towards moisture. Structural adhesives, extruded seals, molded seals, and allotted seals can be utilized to seal battery modules and packs. Moreover, the batteries include poisonous elements, equivalent to fluorinated electrolytes and transitional metals which might contaminate water provides and ecosystems. The seals present enclosure for holding these contained in the pack till it may be disposed of adequately.

Battery Thermal Security

The secure working temperature vary for batteries is outlined as between -40 °C (-104 °F) and 80 °C (176 °F). The most effective efficiency is discovered between 20 °C (68 °F) and 35 °C (95 °F). Working on the excessive temperatures is harmful and might trigger a fireplace.

Causes of Battery Thermal Runaway

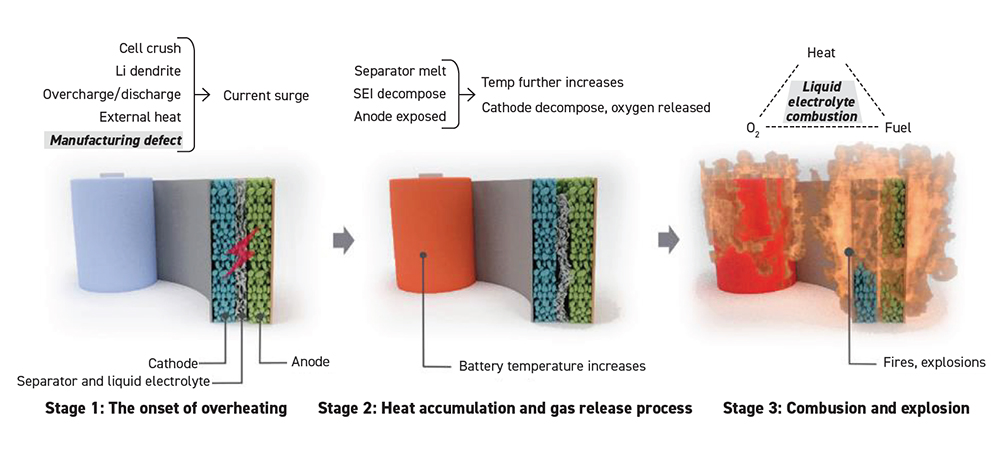

- Thermal Runaway is described as an uncontrolled improve in cell temperature attributable to exothermic reactions contained in the cell.

- Thermal Runaway Propagation (TRP) is the sequential prevalence of thermal runaway inside a battery pack triggered by thermal runaway of a cell in that battery pack.

The scientific consensus on the thermal runaway of Li-ion batteries continues to be growing. Nevertheless, there’s a nonetheless wealth of literature to offer a broad understanding of the method taking place inside a cell that results in its thermal runaway.

The onset of overheating is almost certainly attributable to a producing defect that results in inside brief and a consequent present surge. Such inside brief can even consequence from cell crush, Li dendrite formation, overcharge/discharge, or exterior warmth. The present surge produces spike in temperature. If not dissipated rapidly, this ends in separator soften, SEI layer decomposes, and anode is uncovered. Because the temperature will increase additional, cathode decomposes, and oxygen is launched from cathode lattice construction. A self-sustaining fireplace cycle is fashioned with gas in type of electrolyte, oxygen and warmth. At an onset-temperature, the cell blasts into a fireplace and if this warmth, fireplace and gases aren’t managed correctly, this may cascade into thermal runaway of neighboring cells.

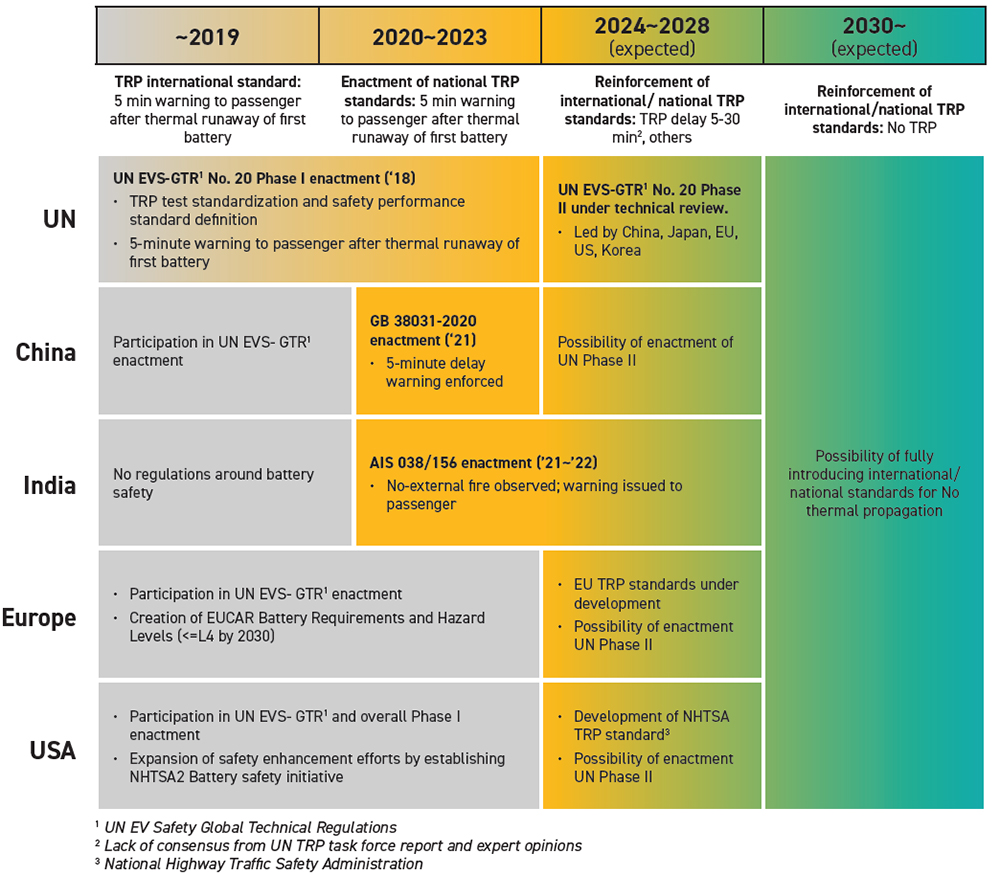

Regulatory Panorama on Thermal Propagation

Rules on battery security have been advancing all through the world in final decade. UN EVS-GTR No. 20 Section I used to be enacted in 2018 that amongst different battery security protocols, enacts a 5 min warning to passenger after thermal runaway of first battery is detected. Since then, the regulation has been adopted in Europe and USA. China enacted GB 38031 in 2020 that adopted the identical 5 min warning. India enforced rules round battery security by their AIS 038/156 enactment in 2021. It describes numerous security take a look at for batteries and battery pack. Nevertheless, no 5 min warning is required.

Presently, US, Europe, and Japan are working in direction of Section II of UN-EV GTR No 20, which is anticipated to come back into impact earlier than finish of this decade. The expectations are the rules will turn out to be extra stringent round battery security, with chance of introducing no thermal runaway propagation.

Operational and Thermal Runaway Security Options

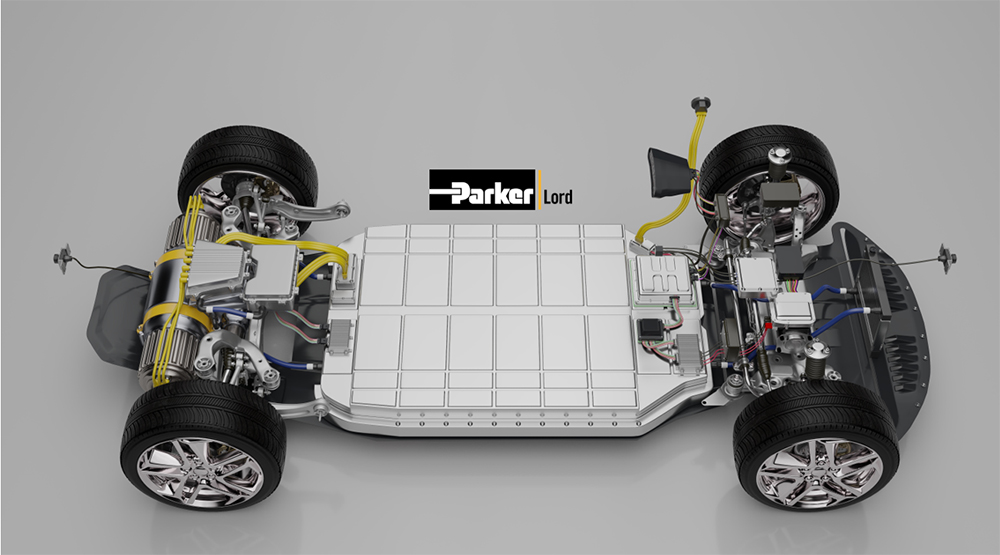

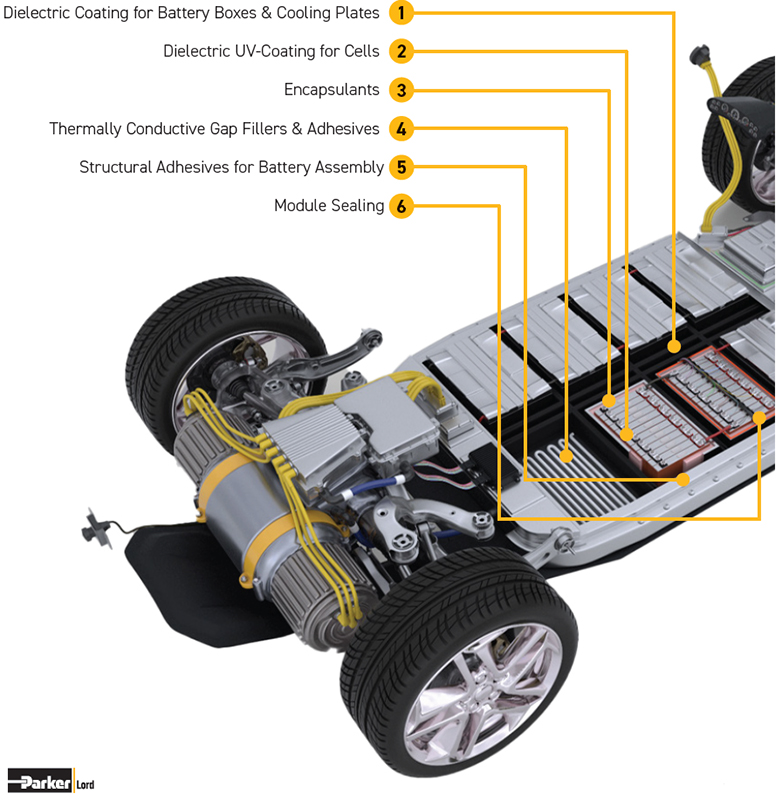

To guard the EV battery, Parker Lord has taken a number of steps to cut back the specter of thermal runaway. These options may be seen within the meeting across the battery.

1 & 2 (Coatings): Coatings for batteries can be found as a dielectric epoxy coating or ultra-violet (UV) remedy dielectric coating. Utility areas for coatings embody the cooling plate, battery pack enclosure, prismatic cell can enclosure and cylindrical cell can enclosure. Increased power density requires highly effective high-voltage batteries. Increased voltage subsequently requires larger precaution in stopping arcing between electrical elements and a necessity for elevated battery security. One main space of focus to attain that is to enhance electrical isolation by utilizing dielectric supplies, equivalent to Parker Lord’s Sipiol UV remedy coating and warmth remedy epoxy coating.

3, 4 & 5 (Thermal Administration Supplies): Essentially the most used thermal administration supplies are hole fillers, thermally conductive adhesives, in addition to potting and encapsulants. These supplies are used on the cell-to-cooling plate, module-to-cooling plate, intra-cell potting, and enclosure potting. Parker Lord’s CoolTherm® thermal administration portfolio is acknowledged for its reliability and customized options to be used in electrical automobiles, power storage methods, motors and different energy electronics. These options improve efficiency, reliability and security whereas delivering tailor-made merchandise to handle the warmth and elevated energy density in electrical automobiles.

6 (Sealants & Adhesives): Structural adhesives and sealants for thermal administration embody using non-reworkable adhesives in addition to reworkable sealants. They’re used for enclosure bonding and sealing in addition to module bonding and sealing. Parker Lord’s adhesives present a structural bond and cut back the quantity of mechanical fixturing required. In addition they enable larger design flexibility and the flexibility to bond dissimilar substrates. These structural adhesives can present a structural or non-structural seal for battery modules and packs to maintain battery cells protected against the weather and enhance security.

Your Associate in Innovation

Improvements in supplies and applied sciences play a vital function in advancing the reliability, effectivity and security of electrified transportation. Because of their market main security options, Parker Lord works along with their clients to propel the transition towards sustainable and electrified transportation ecosystem.

If in case you have questions, attain out to Parker Lord at present.

[ad_2]