[ad_1]

EV battery applied sciences

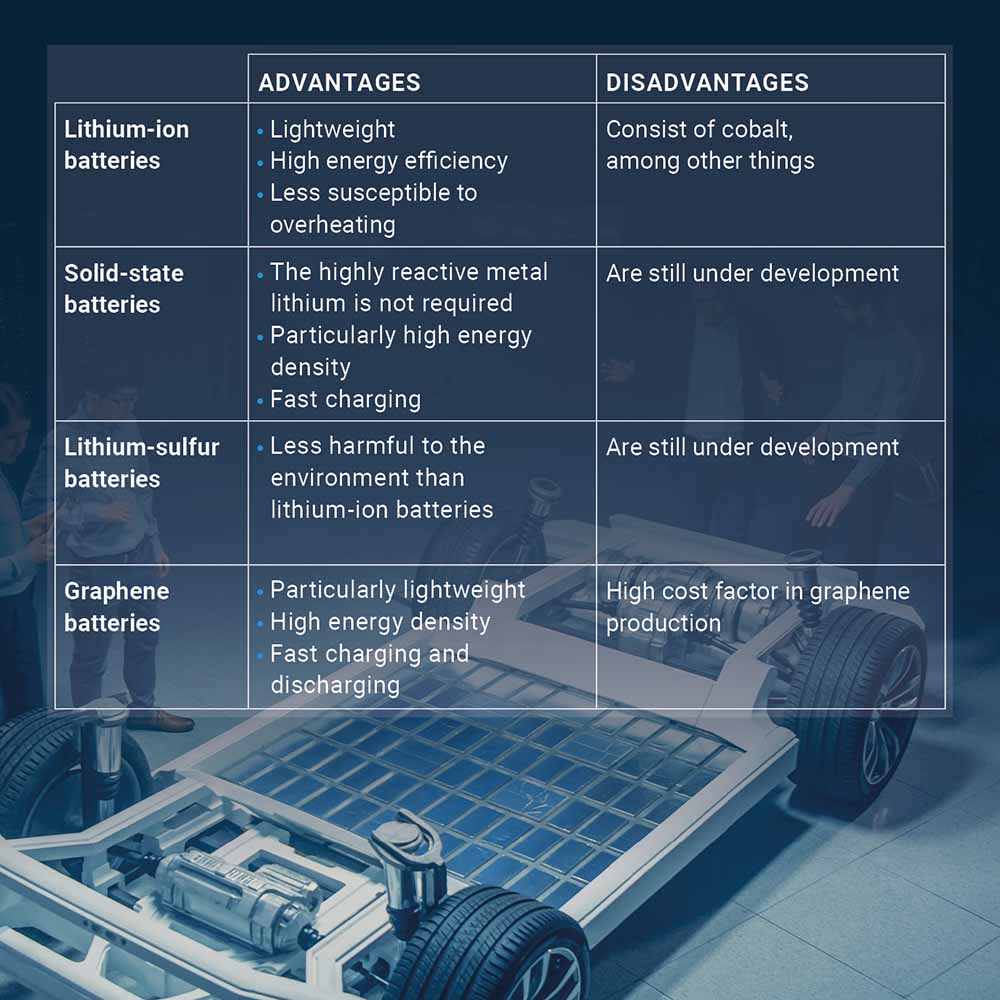

Lithium-ion batteries are comparatively light-weight, exhibit excessive vitality effectivity, and are much less prone to overheat at excessive temperatures. In comparison with different battery sorts, Li-ion takes longer to discharge, thereby providing journey ranges as much as 500+ miles on a full cost. In North America and Europe, EV Li-ion batteries make use of both nickel, manganese, and cobalt (NMC) or nickel, manganese, cobalt, and aluminum (NMCA). Extensively utilized in China, lithium-iron-phosphate (LFP) reveals decrease vitality densities, which require bigger battery sizes to supply vitality ranges akin to NMC-based batteries.

Underneath growth, solid-state batteries present nice promise to be used in future EVs. Stable- state batteries can keep away from the usage of the extremely reactive steel lithium. Electrolytes are strong supplies such polymers, ceramics or glass. Anodes could be graphite or silicon, and cathodes could be nickel-based supplies. Stable-state batteries require much less area and supply larger vitality densities than Li-ion batteries. Consequently, solid-state batteries might double the vary of electrical automobiles. The solid-state electrolyte permits ions to maneuver extra rapidly between the battery anode and cathode, enabling sooner charging.

One other future different to Li-ion, lithium-sulfur, is much like strong state. Stable-state batteries supply an extended vary than Li-ion batteries and are more cost effective to supply. The assumption in Europe is that lithium-sulfur batteries current much less of an impression on the surroundings in comparison with Li-ion batteries product of cobalt.

In comparison with Li-ion batteries, graphene batteries are lighter, bodily stronger, and dissipate warmth higher in the course of the cost/discharge cycle, limiting the danger of overheating and fires. Moreover, graphene batteries can retailer bigger quantities of vitality in the identical measurement bundle and recharge sooner. Vital challenges to mainstream adoption embrace scalability of graphene manufacturing, cost-effectiveness, and integration into current battery manufacturing processes.

Stated to be cheap and highly effective, zinc-air batteries ship energy when oxygen oxidizes zinc. Nevertheless, oxidation degrades battery efficiency, a barrier to huge use of zinc-air batteries.

Rising battery voltage and complete kWh capability

EV battery packs are growing in voltage and capability to handle the journey distance problem. Some automobiles in the marketplace have 800 V battery packs. Giant automobiles corresponding to vehicles, trains, and airplanes will quickly make use of even larger battery voltages. Larger voltages scale back the present necessities, which reduces the scale of the current-carrying wires. Smaller wiring assemblies scale back car weight, contributing to better car effectivity and longer drive distance.

An 800 V battery requires over 200 Li-ion 4.2 V cells, yielding a nominal voltage of 830V. The voltage on the battery can rise an extra 20 to 30 V throughout regenerative breaking, leading to a battery voltage that may attain 860 V. Having a switching energy provide, for instance, with a flyback converter topology, to cost the take a look at system requires a circuit that’s 150 V to 200 V larger than the battery voltage. Subsequent, add in 20% headroom, and the circuit can have a most voltage of round 1.3 kV. At that voltage, a take a look at system will want a supply voltage capability of 1500 to 2000 V to check and cost 800 V and better battery packs.

Along with larger voltage EV batteries, battery capability is growing as effectively. No less than one producer is utilizing a 100 kWh battery pack to increase drive distance. To scale back recharge time, corporations are growing 250 kW charging programs that may add as much as 180 miles of drive distance in 15 to twenty minutes.

The testing problem

Battery take a look at programs must evolve to check the upper voltage and better capability EV battery packs. As indicated, take a look at programs will want voltages to exceed 1000 V and energy over 250 kW capability to check a battery’s most voltage and its skill to just accept a excessive present cost fee. A high-voltage and high-power system will allow battery biking to make sure the battery pack meets its voltage-time discharge curve specification and to estimate cycle life underneath quick charging situations.

Different assessments embrace:

- Pulse assessments that require the battery to ship or take up excessive present in brief intervals for the evaluation of battery thermal design and state of cost (SOC)

- Drive cycle simulation to evolve to straightforward drive simulation assessments corresponding to Federal Check Process (FTP-75)

- DC inner resistance to evaluate a battery’s state-of-health (SOH)

- Insulation resistance to establish defects that may scale back battery effectivity and trigger issues of safety.

Some take a look at programs have to be able to vibration and shock testing, which is crucial for the reliability testing of off-road automobiles. Nevertheless, this testing is a top quality assurance take a look at quite than a manufacturing take a look at carried out on all battery packs.

Batteries could be operated in cycles with bidirectional energy provides. Units corresponding to these manufactured by EA Elektro-Automatik, have energy ranges as excessive as 30 kW and 60 kW. With these provides, one 42U excessive take a look at rack can have a 300 kW capability whereas consuming solely 6.5 sq ft of producing flooring area. With EA provides having a novel true autoranging output (or enter) that permits supply (or absorption of full energy right down to 1/3 of the provision’s rated voltage, one 300 kW rack can assist 2.4 kA.

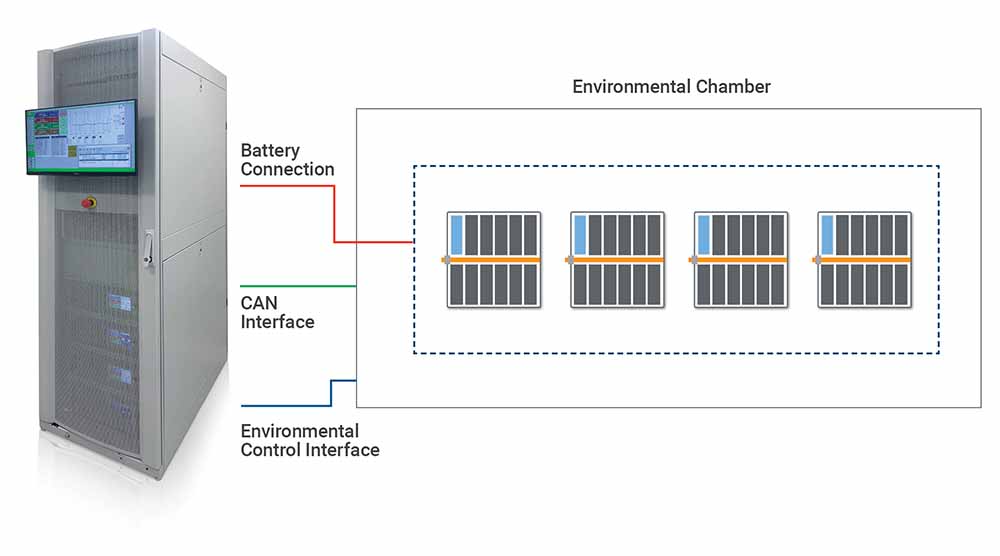

Testing massive, high-capacity battery packs necessitates {that a} battery take a look at system has safety options to stop injury to battery packs and the take a look at system. Programs want to watch battery temperature, present security checks to stop reverse polarity connections, and make sure the battery is sufficiently pre-charged to a protected degree earlier than it might settle for a big cost present.

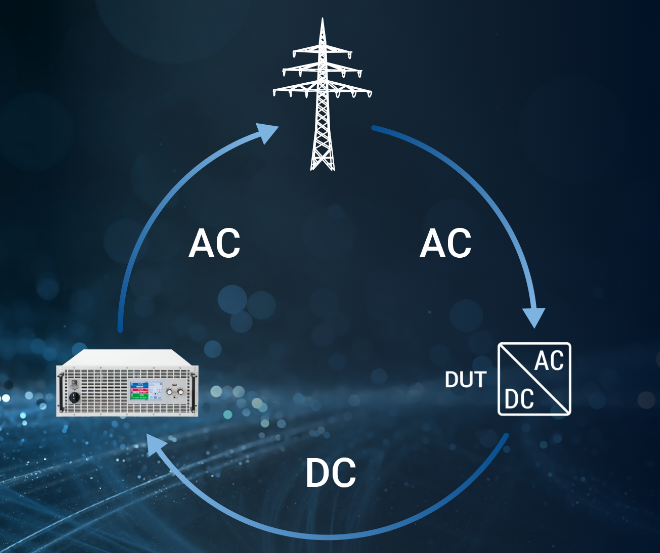

At such high-power ranges, the bidirectional energy provides (or digital hundreds) can save substantial utility prices if they’re regenerative and effectively return absorbed energy to the AC grid. For instance, EA bidirectional energy provides and hundreds can return absorbed vitality with distinctive effectivity—as much as 96.5%.

Performing the heartbeat assessments and drive cycle simulations requires a take a look at system with quick slew charges and excessive information acquisition charges for information seize. The programs additionally want waveform era functionality for the drive cycle simulations.

With rising manufacturing volumes, growing throughput is crucial. Whereas the battery pack dictates the pace of testing, extra take a look at capability can generate elevated throughput. A system that may enhance energy capability into the MW vary can enhance the variety of batteries examined concurrently to extend throughput. Additional particulars could be present in our white paper, which you’ll be able to obtain freed from cost.

Necessities for the battery take a look at system producers

New EV batteries will probably be popping out of the lab and onto the market quickly. They may have larger voltages, larger capability, and the power to recharge rapidly. EV battery take a look at programs might want to have the voltage ranges, quantities of energy, security options, and throughput to check the brand new batteries for a rising EV market. These take a look at programs will want a return on funding from utility value financial savings and manufacturing overhead financial savings. EA is one battery take a look at system producer that’s addressing these challenges.

[ad_2]