Researchers from Germany’s Fraunhofer Institute for Machine Instruments and Forming Expertise IWU have teamed up with companions within the COOLBat joint analysis undertaking to develop next-generation battery enclosures for EVs.

The COOLBat undertaking focuses on making lighter enclosures to scale back energy consumption and enhance driving vary by combining particular person methods, packing extra features right into a smaller set up area and utilizing new heat-conductive supplies and bio-based flame-retardant coatings.

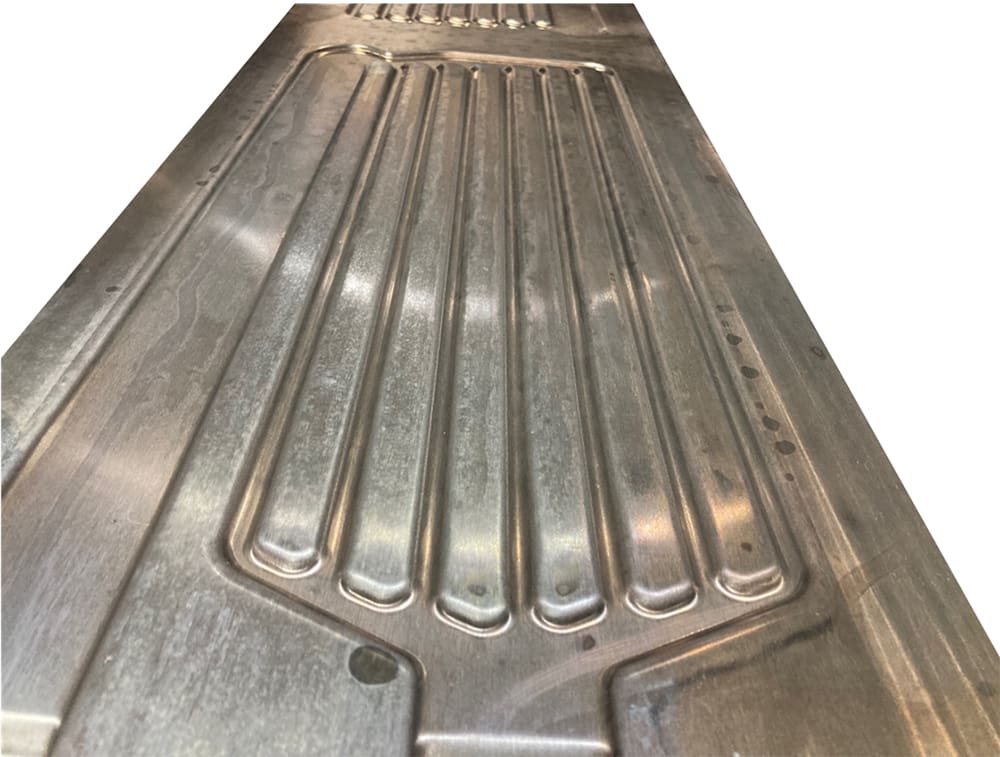

The researchers have explored combining particular person methods within the enclosure that beforehand carried out thermal and mechanical features individually. The cooling unit perform is mixed with that of underride safety in a single element, the bottom plate.

Aluminum foam inside the bottom plate absorbs the affect vitality from stone impacts and accidents. Mixed with a phase-change materials (PCM), a form of wax that can be utilized to retailer and later launch thermal and cooling vitality, the aluminum foam additionally reduces the quantity of vitality wanted to chill the battery.

This configuration protects the battery cells from mechanical masses and overheating directly. A fluid flows via the channels, cooling the cells from beneath and from the edges. This reduces the electrical energy wanted to chill the cells and eliminates the necessity for cooling components elsewhere within the automobile.

One of many goals of the undertaking is to exchange the heavy conductive pastes with ecofriendly heat-conductive supplies to attach the battery module for thermal functions. To do that, the researchers are utilizing a plasma course of to metallize open-pored reusable foams which can be then positioned within the areas between the battery and enclosure in pad kind.

A brand new flame-retardant coating utilized to the underside of the enclosure lid prevents fireplace from spreading from the battery cells beneath. The earlier metal enclosure lid has been changed with a brand new fiber composite lid, lowering the element’s mass and making it attainable to reuse the lid.

The researchers are utilizing the Mercedes-Benz EQS battery as a reference and technological demonstrator.

Future plans name for the undertaking’s outcomes to be prolonged to different functions and industries that use giant batteries, similar to in trains, plane and boats.

“We’re specializing in functionally built-in constructions. Duties that was once dealt with by completely different modules contained in the battery are being built-in right into a single element—the bottom meeting, on this case—to shrink the set up area and streamline interfaces,” stated Rico Schmerler, a undertaking supervisor and scientist within the Battery Techniques division at Fraunhofer IWU. “These base plates will present safety from overheating and avert injury to the battery core in case of an accident.”

Supply: Fraunhofer Institute for Machine Instruments and Forming Expertise IWU