[ad_1]

Underneath Hearth: Reevaluating Torch and Grit Testing Parameters

The protection of Li-ion batteries depends on containing single-cell thermal runaway (TR) occasions in order that they can not propagate into adjoining cells, triggering a cascading failure. Whereas the thermal power launched throughout a runaway occasion can take a number of pathways, probably the most vital are:

- Cell-to-cell conduction

- Strong-, liquid-, and gas-phase ejecta launched from the misbehaving cell.

The primary will be managed with high-performance insulation supplies which, when positioned between cells, act as a firewall. Because the world’s highest performing insulation supplies, aerogel-based thermal limitations have successfully solved the problem of cell-to-cell (C2C) conduction.

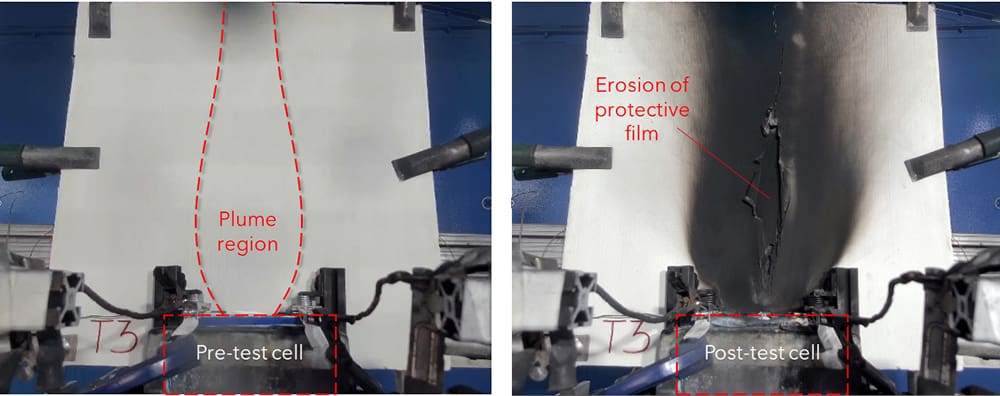

The secure dissipation of ejecta is a tougher job. The high-velocity, high-temperature jets that emerge throughout a cell rupture can shortly soften and/or erode even strong aluminum. To raised perceive this mixed thermal and abrasive assault, engineers typically flip to the UL 2596 take a look at normal for steering. This technique makes use of an array of burning Li-ion cells to evaluate the thermal and mechanical efficiency of battery enclosure supplies. Lately, the usual was revised to incorporate a benchtop experimental technique of simulating publicity to battery-fire ejecta, however with out the batteries. This new torch-and-grit (TaG) technique directs the flame from a propane torch at a goal pattern, whereas periodically injecting high-velocity grit into the stream to copy battery ejecta and their results on adjoining parts.

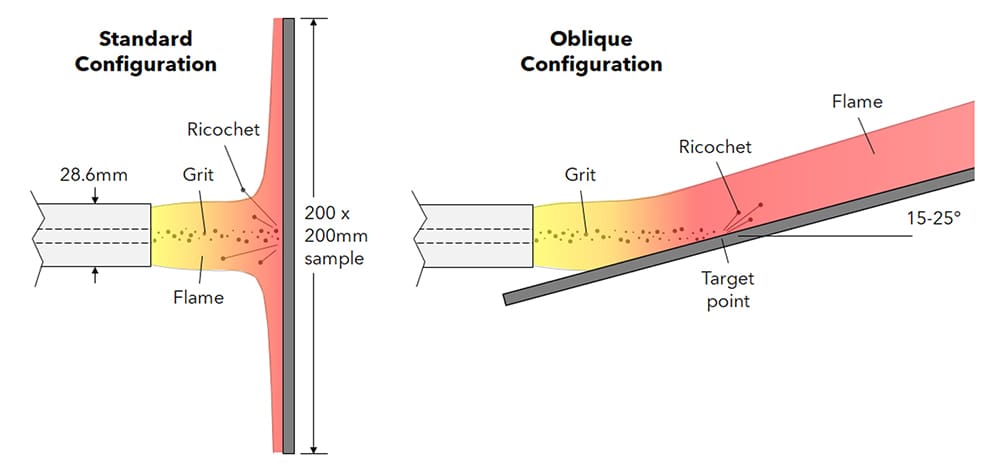

The UL 2596 normal has been very useful within the analysis of pack covers, which typically exist in shut proximity with, and regular to Li-ion cell venting. Nevertheless, outdoors of the quick impingement zone, the UL 2596 take a look at parameters are probably too conservative to simulate publicity all through the remainder of the pack. In different phrases, parts that may survive module- and pack-level thermal propagation testing will typically fail UL 2596, limiting its worth as a screening device for non-pack-cover purposes.

Nevertheless, latest thermal runaway testing means that UL 2596 will be modified to enhance its accuracy for non pack cowl parts. These exams positioned prismatic cells immediately in opposition to and parallel to a goal pattern such that, when triggered, the ejecta impacted the pattern at an indirect angle. The ensuing “glancing blow” was discovered to be extra typical of what’s skilled by parts farther away from the impingement zone. It additionally means that canting the UL 2596 goal to 15-25° from parallel would possibly present a greater simulation of far-field impingement.

After every take a look at, the ejected strong particles had been collected for evaluation. The group reviewed the particle measurement, hardness, and chemistry to raised perceive their conduct throughout thermal runaway occasions. The evaluation revealed a major proportion of huge (>700µm), non-spherical remnants of aluminum and copper foils. Whereas their preliminary ejection velocity is excessive, the a number of inelastic impacts they expertise inside the confined house of a battery pack shortly bleed off momentum. The ensuing crumpled items possess a low ballistic coefficient and can subsequently observe the fluid-dynamic streamlines towards the pack vent – assume feathers, not cannonballs.

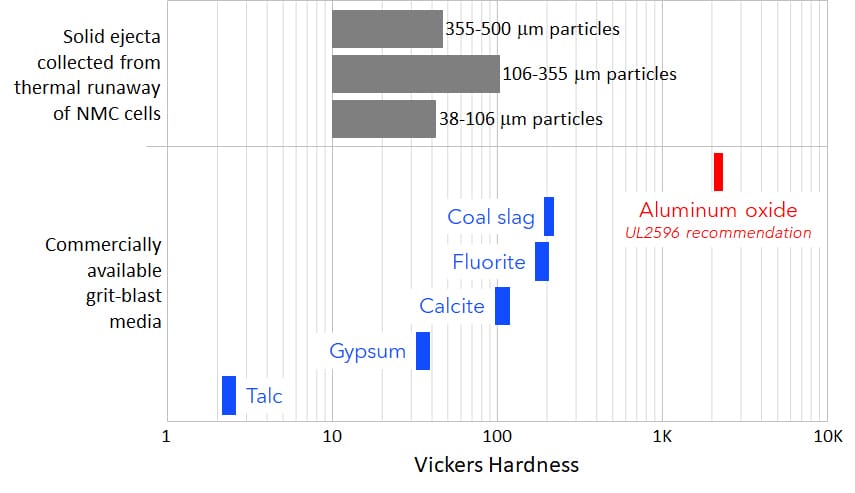

Smaller particles, possessing a Sauter imply diameter (D32) of 240 microns, had been composed primarily of oxygen, aluminum, nickel, and carbon. Regardless of their metallic composition, these particles had been smooth and simply powdered within the hand. Vickers hardness testing was carried out, displaying many of the ejecta being considerably softer than UL 2596’s really useful grit, aluminum oxide. This implies that additional modifying the take a look at with a softer abrasive would produce outcomes extra applicable for surfaces outdoors the impingement zone.

Associate with scientists and engineers who deeply perceive the complexities of thermal runaway occasions. Go to our web site to study extra about PyroThin® cell-to-cell limitations and request a gathering with our technical group to debate your software.

[ad_2]