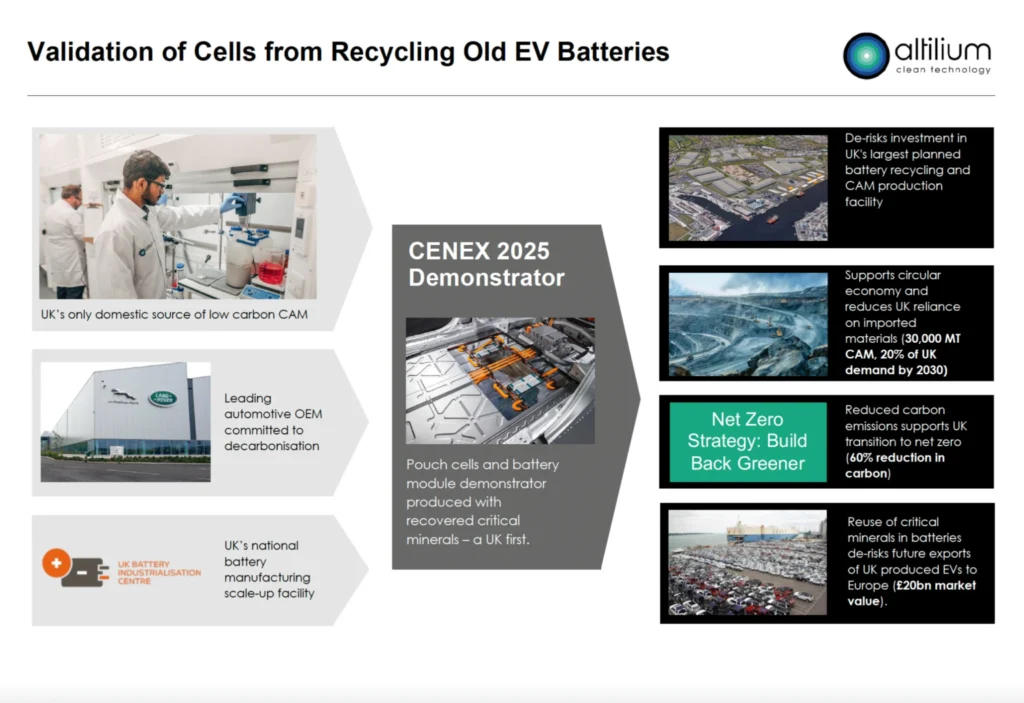

UK-based battery supplies recycling firm Altilium has introduced a undertaking to supply EV battery cells utilizing cathode energetic supplies recovered from end-of-life EV batteries and validate them to be used in automobiles for UK-based luxurious automotive producer JLR.

The undertaking is supported by the Superior Propulsion Centre UK underneath the most recent spherical of its Superior Path to Market Demonstrator (ARMD) competitors.

Altilium says its EcoCathode course of, used to recuperate such supplies as lithium, cobalt and nickel, ends in a 60% discount in carbon emissions by lessening the necessity for newly mined supplies.

Battery manufacturing will happen on the UK’s nationwide battery manufacturing scale-up facility, the UK Battery Industrialisation Centre (UKBIC), utilizing recovered supplies produced by Altilium in Devon at its mini-commercial ACT2 facility and its ACT1 pilot. JLR will conduct validation research on the pouch cells at its battery testing services.

Altilium COO Christian Marston stated, “By demonstrating that EV battery cells constituted of recovered supplies can meet the rigorous requirements of the automotive business, we’re not solely lowering the environmental impression of battery manufacturing but additionally supporting the UK’s efforts to construct a extra sustainable and resilient EV provide chain.”

Supply: Altilium