With the increasing push towards sustainability and efficiency, the electrification of industrial vehicles is not just a technological milestone but a necessity. As electric vehicles (EVs) revolutionize transportation and extend their reach into diverse industrial sectors, the demand for robust and reliable battery systems becomes ever more critical.

Revolutionizing Industrial Battery Technology

Industrial batteries, particularly those used in EVs, are subject to extreme conditions and rigorous demands. These batteries must maintain optimal performance over extended periods, often in environments where conditions can be severe. The efficiency of a battery is significantly hampered if it cannot effectively manage the heat generated during operation. Poor thermal management can lead to decreased performance, safety hazards like thermal runaway and an ultimately reduced lifespan.

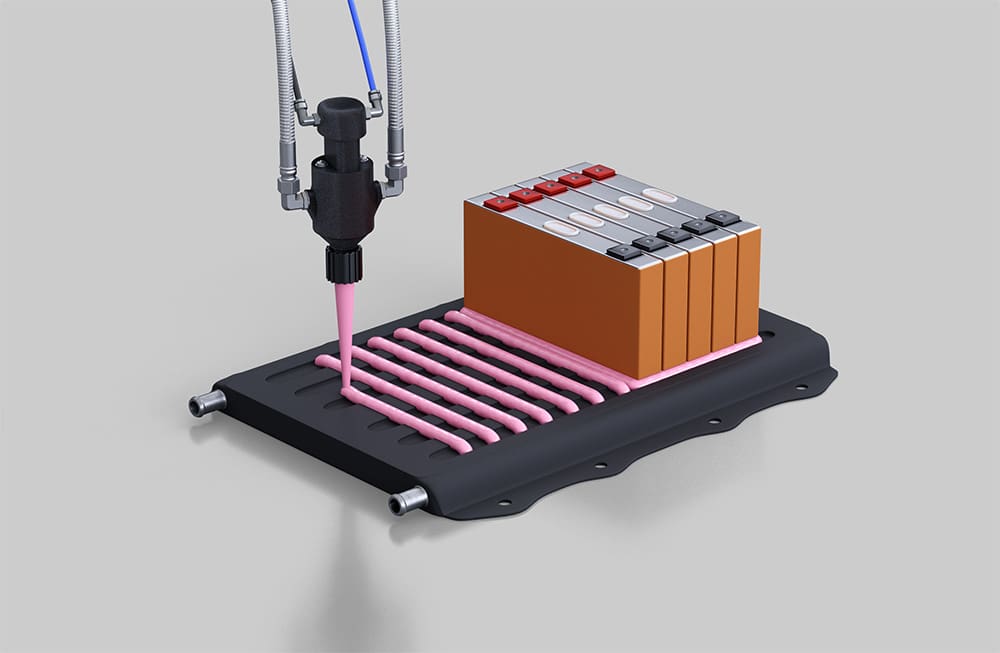

Moreover, EV batteries need to demonstrate remarkable durability and reliability to withstand the mechanical stresses and vibrations inherent in industrial applications. This is where thermally conductive structural adhesives play a critical role, ensuring the battery components remain securely bonded while facilitating effective heat dissipation.

Thermal Management and Durability

Poor thermal management in batteries can lead to decreased performance and safety hazards. Parker’s CoolTherm® TC-2002, a two-component adhesive system, is engineered for superior thermal conductivity. It enhances heat dissipation, reduces overheating risks and promotes battery longevity. The structural adhesive’s robust mechanical bonding maintains structural integrity, vital for industrial applications where batteries are subject to constant motion and vibration. Additionally, properties like flame retardancy and electrical isolation make CoolTherm TC-2002 an optimal solution for safety and performance reliability.

Real-World Industrial Applications

In real-world scenarios, Parker’s CoolTherm thermal management materials have been instrumental in enhancing the performance and reliability of EV batteries used in sectors such as construction, mining, agriculture and logistics. An electric forklift manufacturer integrating CoolTherm TC-2002 into their battery design, for example, will achieve improved heat management and structural support. This integration not only extended the battery life but also contributes to the forklift’s overall energy efficiency and operational safety.

Emerging Markets Fueling Advanced Battery Demand

Beyond traditional automotive applications, several emerging non-automotive EV markets are rapidly adopting advanced battery technologies. Each sector presents unique demands and opportunities for growth.

- The Warehouse Revolution: The warehouse sector, which includes electric forklifts, personnel carriers and stock chasers, is rapidly shifting from nickel batteries and propane powertrains to lithium-ion battery powertrains. Lithium-ion battery technology has enabled greater adoption of electric power versus propane or natural gas but is also driving a switch from nickel batteries to Li-ion. The market for electric warehouse equipment is projected to experience substantial growth due to rising demand from the e-commerce industry, a growing focus on sustainability and advancements in battery technology.

- Transforming Transportation: Trucks and Buses: Electric trucks and buses are gaining momentum, spurred by technological innovations and stringent emission regulations. The anticipated cost parity with diesel trucks and buses accelerates their adoption, further supported by battery advancements promising enhanced performance and reduced environmental impact.

- Construction Industry Electrification: Electrification in construction equipment is gaining traction, with electric machinery requiring batteries that withstand harsh environments. The heavy-duty electric vehicle battery market, including those used in construction applications, is adapting to these needs with ruggedized battery designs and is expected to experience significant growth, with forecasts indicating a Compound Annual Growth Rate (CAGR) between 10% and 15% over the next decade. This growth is driven by increasing environmental regulations, rising fuel costs and advancements in battery technology that can better suit demanding construction needs. A documented benefit also exists from reduced pollution and worker hazards in poorly ventilated construction environments. Moreover, inner-city noise-related ordinances regulate the operating hours of loud diesel construction equipment, but these restrictions may not apply to quieter electric alternatives.

- The Rise of Electric Motorcycles: Globally, the electric motorcycle market is experiencing exponential growth, with projections indicating an expansion from a $30 billion market to over $140 billion by 2030. This surge is largely fueled by lithium-ion batteries, whose lightweight design and high energy density meet the specific demands of this sector.

- Marine and Aerospace Innovations: Marine and aerospace industries are tapping into advanced battery technologies, with market projections indicating significant growth. These sectors focus on developing batteries that address challenges like corrosion resistance and weight constraints, often involving hybrid systems and renewable energy solutions. The global marine battery market alone is expected to expand from $1.3 billion in 2024 to $5.4 billion by 2032.

Challenges and Solutions in Non-Automotive EV Battery Development

In the realm of non-automotive electric vehicles (EVs), industrial batteries encounter distinct challenges that are critical to their performance and safety. For one, effective thermal management is paramount to prevent overheating and ensure reliability during charging and discharging cycles. Additionally, achieving weight reduction without compromising battery performance is essential for enhancing vehicle efficiency.

The need for robust sealing solutions is equally crucial, as it protects battery enclosures from environmental factors and maintains operational integrity. Furthermore, enhancing the durability and longevity of these batteries is vital to withstand the rigorous demands and conditions they face. Addressing these challenges is fundamental to advancing the capabilities and safety of industrial batteries in non-automotive EV applications.

Parker leverages its expertise in advanced materials and technologies to tackle the formidable challenges faced by battery manufacturers in the non-automotive EV sector. By implementing cutting-edge thermal management solutions, optimal heat dissipation is achieved, safeguarding against overheating and enhancing overall battery reliability.

Additionally, encapsulants and potting compounds, including the CoolTherm portfolio, are designed to improve the durability and longevity of battery packs by providing robust protection and thermal management. Parker tailors these solutions to meet the specific needs of non-automotive EV applications, ensuring optimal battery performance and reduced downtime.

Capturing Opportunities in a Dynamic Market

The demand for advanced battery technologies is set to grow as industries continue to innovate. The industrial battery market reflects a broader commitment to sustainability and operational efficiency, with sectors like construction, transportation and logistics leading the charge. As these industries continue to innovate, so will Parker. With tailored solutions, Parker continues to not only meet but exceed the specific needs of each sector. Parker invites you to explore how their advanced technologies for batteries can empower your operations and drive success in these dynamic markets.

Integrating thermally conductive adhesives, such as Parker’s CoolTherm TC-2002, into battery systems underscores the strides being made to enhance performance and safety. By managing thermal loads effectively, these adhesives extend battery lifespan, improve safety and ensure consistent performance even in challenging environments.

For businesses aiming to capitalize on these market opportunities, understanding the evolving landscape and the role of advanced battery technology is crucial. Parker’s solutions offer a pathway to success, empowering operations across diverse sectors with tailored technologies that meet specific industry needs.

The electrification of industrial vehicles and the rise of non-automotive EV markets signal a new era in battery technology. By addressing key challenges in thermal management and durability, and exploring emerging markets, industries can leverage these advancements to drive growth and innovation.

For more insights into how Parker’s advanced technologies can revolutionize your industrial battery systems, visit their website or reach out to their team to explore the latest in thermally conductive adhesives and other cutting-edge solutions.